金屬材料成形雙語教程(簡體書)

商品資訊

系列名:普通高等教育十二五規劃教材

ISBN13:9787502459772

出版社:冶金工業出版社

作者:余萬華

出版日:2012/08/01

裝訂:平裝

規格:26cm*19cm (高/寬)

商品簡介

名人/編輯推薦

目次

書摘/試閱

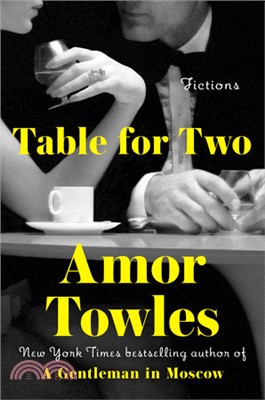

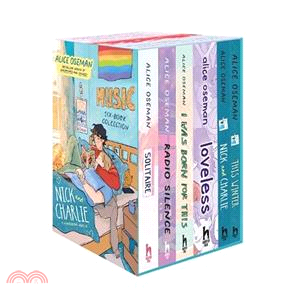

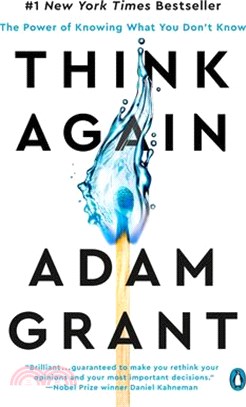

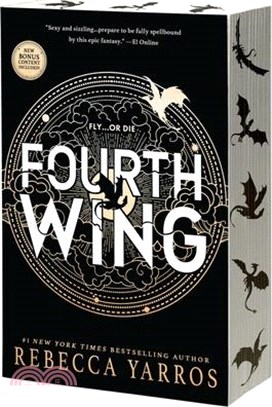

相關商品

商品簡介

《普通高等教育"十二五"規劃教材:金屬材料成形雙語教程》是在Serope Kalpak jian教授等主編的,《Manufacturing Engineering and Technology》及國外有關的優秀教材基礎上,針對我國高校金屬材料加工與控制專業學生的雙語教學需要改編而成的。全書共分8章,包括:材料成形基礎知識,金屬結構特點和結構缺陷,合金相變和組織演變的基本特性等。在此基礎上重點介紹了鑄造、軋制、鍛造、焊接等幾種主要的金屬成形方式、最新成形工藝和相應的質量缺陷及防治方法等。為了便于學生學習,每章章后附有思考題,書后列出了材料加工方面常用單詞中英文對照。在內容組織和結構安排上,力求理論聯系實際,注重學生專業能力的培養,突出實用性、先進性。

名人/編輯推薦

《普通高等教育"十二五"規劃教材:金屬材料成形雙語教程》主要作為大專院校冶金和金屬材料加工與控制專業雙語教學用書,也可作為相關企業在職人員的培訓教材,并可供從事金屬材料研究、生產和應用方面的工程技術人員與管理人員參考。

目次

1 General Introducfion

1.1 What are Material Forming and Manufacturing?

1.2 Examples of Manufactured Products

1.2.1 Paper clips

1.2.2 Incandescent light bulbs

1.3 The Design Process and Concurrent Engineering

1.4 Design for Manufacture and Assembly

1.5 Selecting Materials

1.6 Selecting Manufacturing Processes

1.7 Computer Integrated Manufacturing

1.7.1 Machine control systems

1.7.2 Computer technology

1.8 Quality Assurance and Total Quality Management

1.9 Organization for Manufacture

1.10 Summary

Questions

Note

2 The Structure of Metals

2.1 The Crystal Structure of Metals

2.2 Deformation and Strength of Single Crystals

2.3 Imperfections in the Crystal Structure of Metals

2.3.1 Dislocations

2.3.2 Work hardening(strain hardening)

2.4 Grains and Grain Boundaries

2.4.1 Grain size

2.4.2 Influence of grain boundaries

2.4.3 Grain boundary embrittlement

2.5 Plastic Deformation of Polycrystalline Metals

2.6 Recovery,Recrystallization and Grain Growth

Questions

Note

3 Metal Alloys:Their Structure and Strengthening by Heat Treatment

3.1 Introduction

3.2 Structure of Alloys

3.2.1 Solid solutions

3.2.2 Intermetallic compounds

3.2.3 Two phase systems

3.3 Structure of Alloys

3.4 The Iron Carbon System

3.4.1 Ferrite

3.4.2 Austenite

3.4.3 Cementite

3.5 Heat Treatment of Nonferrous Alloys and Stainless Steels

3.5.1 Solution treatment

3.5.2 Precipitation hardening

3.6 Annealing

3.7 Summary

Questions

Note

4 Metal Casting Process

4.1 Introduction

4.2 Solidiocation of Metals

4.2.1 Pure metals

4.2.2 Alloys

4.2.3 Structure property relationships

4.3 Fluid Flow and Heat Transfer

4.3.1 Fluid flow

4.3.2 Fluidity of molten metal

4.3.3 Heat transfer

4.3.4 Shrinkage

4 3 5 Defects

4.4 Summary

Questions

Note

5 Rolling

5.1 Introduction

5.2 Flat Rolling

5.2.1 Frictional forces

5.2.2 Roll force and power requirement

5.3 Flat Rolling Practice

5.4 Defects in Rolled Plates and Sheets

5.5 Rolling Mills

5.6 SKape Rolling Operations

5.7 Production of Seamless Tubing and Pipe

5.8 Summary

Questions

Note

6 Forging Process

6.1 Introduction

6.2 Open Die Forging

6.3 Impression Die and Closed Die Forging

6.4 Precision Forging

6.5 Coining

6.6 Heading

6.7 Piercing

6.8 Other Operations

6.9 Die Materials and Lubrication

6.10 Forgeability

6.11 Forging Defects

6.12 Summary

Questions

Note

7 The Metallurgy of Welding

7.1 Introduction

7.2 The Welded Joint

7.2 1 Solidification of the weld metal

7.2.2 Heat affected zone

7.3 Weld Quality

7.3.1 Porosity

7.3.2 Slag inclusions

7.3.3 Incomplete fusion and penetration

7.3.4 Cracks

7.3.5 Lamellar tears

7.3.6 Surface damage

7.3.7 ResiduaI stresses

7.4 Weldability

7.5 Weld Design and Process Selection

7.6 Summary

Questions

Note

8 Quality Assurance,Testing and Inspection

8.1 Introduction

8.2 Product Quality

8.3 Quality Assurance

8.4 Total Quality Management

8.4.1 Quality engineering as a philosophy

8.4.2 The ISO 9000 standard

8.5 Statistical Methods of Quality Control

8.6 Statistical Process Control

8.7 Acceptance Sampling and Control

8.8 Reliability

8.9 Destructive Testing

8.10 Automated Inspection

8.11 Summary

Questions

Note

Appendix

References

1.1 What are Material Forming and Manufacturing?

1.2 Examples of Manufactured Products

1.2.1 Paper clips

1.2.2 Incandescent light bulbs

1.3 The Design Process and Concurrent Engineering

1.4 Design for Manufacture and Assembly

1.5 Selecting Materials

1.6 Selecting Manufacturing Processes

1.7 Computer Integrated Manufacturing

1.7.1 Machine control systems

1.7.2 Computer technology

1.8 Quality Assurance and Total Quality Management

1.9 Organization for Manufacture

1.10 Summary

Questions

Note

2 The Structure of Metals

2.1 The Crystal Structure of Metals

2.2 Deformation and Strength of Single Crystals

2.3 Imperfections in the Crystal Structure of Metals

2.3.1 Dislocations

2.3.2 Work hardening(strain hardening)

2.4 Grains and Grain Boundaries

2.4.1 Grain size

2.4.2 Influence of grain boundaries

2.4.3 Grain boundary embrittlement

2.5 Plastic Deformation of Polycrystalline Metals

2.6 Recovery,Recrystallization and Grain Growth

Questions

Note

3 Metal Alloys:Their Structure and Strengthening by Heat Treatment

3.1 Introduction

3.2 Structure of Alloys

3.2.1 Solid solutions

3.2.2 Intermetallic compounds

3.2.3 Two phase systems

3.3 Structure of Alloys

3.4 The Iron Carbon System

3.4.1 Ferrite

3.4.2 Austenite

3.4.3 Cementite

3.5 Heat Treatment of Nonferrous Alloys and Stainless Steels

3.5.1 Solution treatment

3.5.2 Precipitation hardening

3.6 Annealing

3.7 Summary

Questions

Note

4 Metal Casting Process

4.1 Introduction

4.2 Solidiocation of Metals

4.2.1 Pure metals

4.2.2 Alloys

4.2.3 Structure property relationships

4.3 Fluid Flow and Heat Transfer

4.3.1 Fluid flow

4.3.2 Fluidity of molten metal

4.3.3 Heat transfer

4.3.4 Shrinkage

4 3 5 Defects

4.4 Summary

Questions

Note

5 Rolling

5.1 Introduction

5.2 Flat Rolling

5.2.1 Frictional forces

5.2.2 Roll force and power requirement

5.3 Flat Rolling Practice

5.4 Defects in Rolled Plates and Sheets

5.5 Rolling Mills

5.6 SKape Rolling Operations

5.7 Production of Seamless Tubing and Pipe

5.8 Summary

Questions

Note

6 Forging Process

6.1 Introduction

6.2 Open Die Forging

6.3 Impression Die and Closed Die Forging

6.4 Precision Forging

6.5 Coining

6.6 Heading

6.7 Piercing

6.8 Other Operations

6.9 Die Materials and Lubrication

6.10 Forgeability

6.11 Forging Defects

6.12 Summary

Questions

Note

7 The Metallurgy of Welding

7.1 Introduction

7.2 The Welded Joint

7.2 1 Solidification of the weld metal

7.2.2 Heat affected zone

7.3 Weld Quality

7.3.1 Porosity

7.3.2 Slag inclusions

7.3.3 Incomplete fusion and penetration

7.3.4 Cracks

7.3.5 Lamellar tears

7.3.6 Surface damage

7.3.7 ResiduaI stresses

7.4 Weldability

7.5 Weld Design and Process Selection

7.6 Summary

Questions

Note

8 Quality Assurance,Testing and Inspection

8.1 Introduction

8.2 Product Quality

8.3 Quality Assurance

8.4 Total Quality Management

8.4.1 Quality engineering as a philosophy

8.4.2 The ISO 9000 standard

8.5 Statistical Methods of Quality Control

8.6 Statistical Process Control

8.7 Acceptance Sampling and Control

8.8 Reliability

8.9 Destructive Testing

8.10 Automated Inspection

8.11 Summary

Questions

Note

Appendix

References

書摘/試閱

2.4.3 Grain boundary embrittlement

When brought into close atomic contact with certain low melting point metals,a normally ductileand strong metal can crack under very low stresses.Examples are aluminum wetted with a mereury zinc amalgam,or liquid gallium and copper at elevated temperature wetted with lead.or bismuth.These elements weaken the grain boundaries of the metal by embrittlement.We use theterm liquid metal embrittlement to describe such phenomena because the embrittling element is ina liquid state.However,embrittlement can also occur at temperatures well below the meltingpoint of the embrittling element.This phenomenon is known as solid metal embrittlement.

Hot shortness is caused by local melting of a constituent or an impurity in grain boundary at atemperature below the melting point of the metal itself.When such a metal is subjected to plasticdeformation at elevated temperatures(hot working),the piece of metal crumbles and disintegratesalong the grain boundaries.Examples are antimony in copper and leaded steels and brass.Toavoid hot shortness,the metal is usually worked at a lower temperature in order to prevent softening and melting along the grain boundaries.Another form of embrittlement is temper embrittlementin alloy steels,which is caused by segregation(movement)of impurities to the grain boundaries.

2.5 Plastic Deformation of Polycrystalline Metals

If a piece of polycrystalline metal with uniform equiaxed grains having equal dimensions in all directions is subjected to plastic deformation at room temperature(cold working),the grains become deformed and elongated.The deformation process may be carried out either by compressingthe metal,as is done in forging to make a turbine disk,or by subjecting it to tension,as is donein stretching sheet metal to make a car body.

主題書展

更多

主題書展

更多書展今日66折

您曾經瀏覽過的商品

購物須知

大陸出版品因裝訂品質及貨運條件與台灣出版品落差甚大,除封面破損、內頁脫落等較嚴重的狀態,其餘商品將正常出貨。

特別提醒:部分書籍附贈之內容(如音頻mp3或影片dvd等)已無實體光碟提供,需以QR CODE 連結至當地網站註冊“並通過驗證程序”,方可下載使用。

無現貨庫存之簡體書,將向海外調貨:

海外有庫存之書籍,等候約45個工作天;

海外無庫存之書籍,平均作業時間約60個工作天,然不保證確定可調到貨,尚請見諒。

為了保護您的權益,「三民網路書店」提供會員七日商品鑑賞期(收到商品為起始日)。

若要辦理退貨,請在商品鑑賞期內寄回,且商品必須是全新狀態與完整包裝(商品、附件、發票、隨貨贈品等)否則恕不接受退貨。

優惠價:87

146

海外經銷商無庫存,到貨日平均30天至45天